How to Plan a 3D Scanning Project for Industrial Projects

Industrial retrofits are some of the most challenging engineering projects in the world. Whether replacing aged piping, modifying vessels, or modernizing process infrastructure, the success of any retrofit begins with one thing: knowing exactly what already exists.

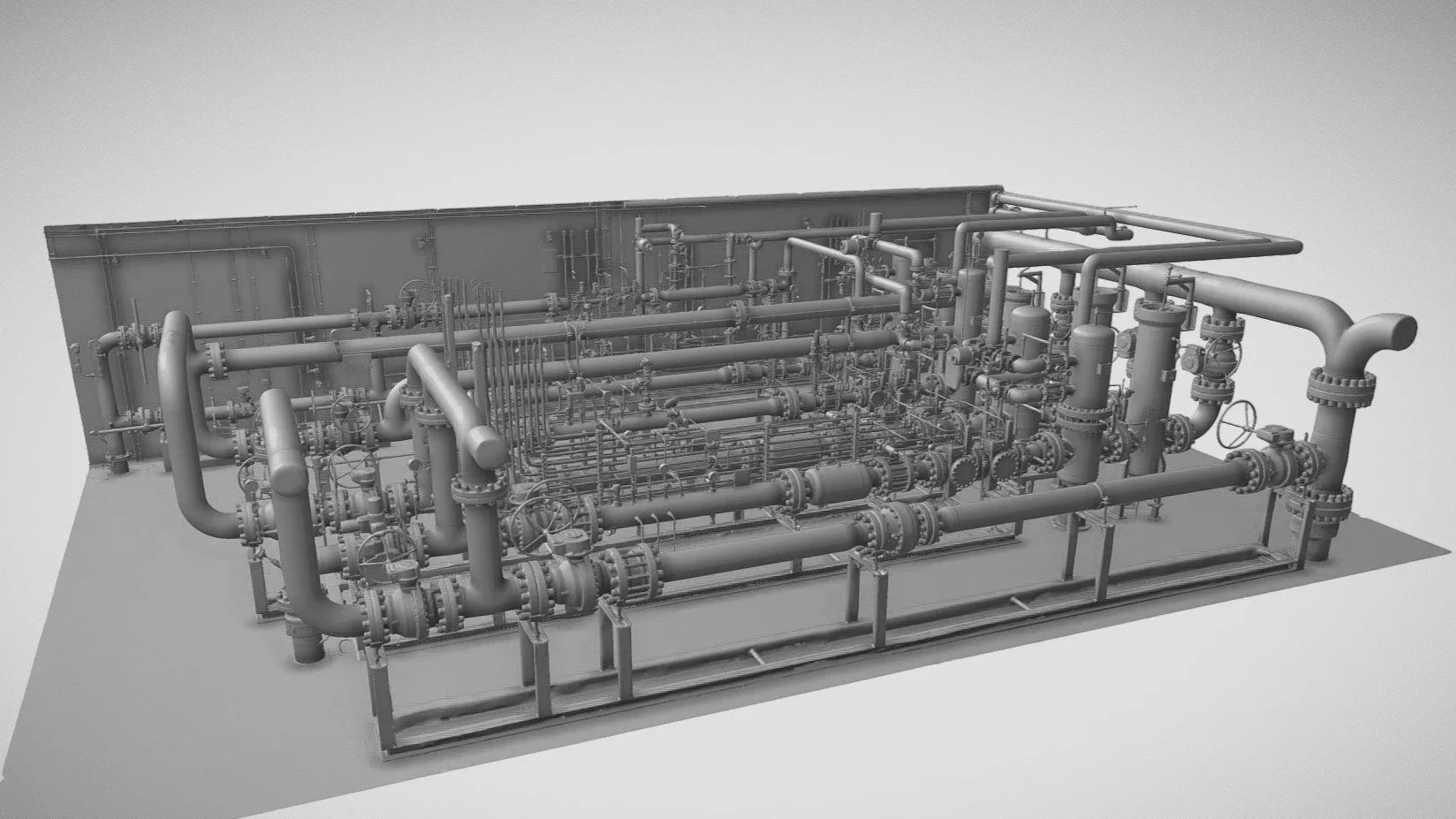

3D scanning has become the gold standard for capturing accurate as-built data before design and fabrication begin. But achieving reliable, usable scan data isn’t just about owning the right equipment—it’s about careful planning. A well-structured scanning plan defines scope, ensures safe and efficient access, selects the right scanning methodology, and produces deliverables that integrate seamlessly into engineering workflows.

This article outlines best practices for planning a 3D scanning project in an industrial retrofit environment.

1. Define the Scope and Objectives

The foundation of any successful scan lies in a clear definition of purpose. Before mobilizing to site, engineers and scanning specialists must answer key questions:

What needs to be captured?

Identify the specific areas or systems relevant to the retrofit—such as tie-in points, vessel nozzles, or pipe racks. Avoid scanning unnecessary zones to reduce data volume and time on site.Why is the data being collected?

The intended use of the scan determines the required level of accuracy and model detail. A full process plant digital twin demands higher precision and density than a simple tie-in verification.What deliverables are expected?

Define the output early—point cloud only, registered data set, 3D CAD model, or BIM environment. Align expectations between the scanning team and the engineering designers.

A documented scope statement, including accuracy tolerances and coordinate system requirements, eliminates ambiguity and sets measurable quality benchmarks.

2. Plan for Site Access and Safety

Industrial facilities are rarely easy places to scan. Tight spaces, live equipment, and safety restrictions all impact the workflow. Proper access planning ensures both safety and efficiency.

Coordinate with Operations: Schedule scanning during low-activity periods or planned outages where possible. Obtain necessary work permits, hot-work clearances, and safety orientations.

Assess Physical Constraints: Identify confined spaces, elevated areas, and potential line-of-sight obstacles that could limit scanner visibility.

Use the Right Tools for the Environment:

Long-range LiDAR scanners for open process areas or exterior structures.

Compact handheld scanners for confined or obstructed spaces.

Tripod mounts or magnetic platforms for stability in vibration-prone zones.

Prioritize Safety: The planning phase should include hazard assessments, PPE requirements, and rescue procedures for rope access or elevated work.

A well-organized site plan reduces re-scans, minimizes exposure to hazards, and ensures consistent data coverage.

3. Choose the Appropriate Scanning Methodology

Different projects demand different scanning techniques. Selecting the right combination is essential for balancing speed, accuracy, and practicality.

Static Terrestrial Scanning (LiDAR):

Best suited for large, complex environments like refineries, power plants, and ship engine rooms. Delivers high-accuracy data (±1–3 mm) but requires multiple setups and line-of-sight between scans.

Handheld Scanning:

Ideal for confined spaces, equipment-packed modules where maneuverability is key and objects where a higher detail and accuracy may be required. Provides higher accuracy than Lidar (0.1mm or better typical) but may require objects and areas be prepared for scanning, as some handheld scanners may require marker targets on the object.

Hybrid Approaches:

Many retrofit projects combine both methods—long-range LiDAR for structural frameworks and handheld scans for congested internal zones. These data sets are then merged during registration to form a single cohesive model.

Choosing the right methodology also means understanding data registration workflows, scan density requirements, and coordinate alignment to plant benchmarks or survey control.

4. Establish Data Processing and Deliverables

Capturing the scan is only half the work—processing and delivering usable data are where value is realized.

Registration and Alignment: Combine multiple scans into a unified point cloud or mesh file, potentially aligned to existing plant coordinates.

Noise Filtering and Cleanup: Remove irrelevant points (e.g., workers, scaffolding, dust) for a clean and usable dataset.

Modeling and Conversion: Convert point clouds or mesh files into intelligent 3D models or surface meshes compatible with engineering software such as AVEVA E3D, AutoCAD Plant 3D, or SolidWorks.

Quality Verification: Apply deviation checks against benchmarks or previous surveys to ensure accuracy meets the project’s tolerance requirements.

Deliverables: Typical outputs include registered point clouds (.RCP, .E57,), or mesh files (.STL, .OBJ), CAD models, isometric drawings, and visualizations for project documentation or presentations.

Deliverables should be formatted and verified according to the client’s workflow, ensuring direct usability for design and fabrication teams.

5. Validate and Communicate Results

Once deliverables are complete, a review meeting between the scanning provider and the engineering team ensures that the results meet design intent. Visualization of the data in review software (e.g., Navisworks, ReCap, or ArtedCloud) allows designers to explore the scan, verify tie-in points, and confirm completeness.

Good communication at this stage prevents downstream issues—especially when scan data informs critical fabrication dimensions or layout changes.

Conclusion

Planning a 3D scanning project for an industrial retrofit requires a structured approach that balances technical precision with site realities. When scope, access, methodology, and deliverables are properly defined, 3D scanning transforms from a data-collection task into a cornerstone of project success.

The payoff is clear: faster design validation, fewer site revisits, safer workflows, and confidence that every retrofit component will fit exactly as intended. In short, thoughtful planning turns digital accuracy into real-world efficiency.