Clash Detection in Piping Systems: How 3D Scanning Reduces Risk

Industrial facilities—whether refineries, chemical plants, or offshore vessels—are often packed with layers of piping, structural steel, and equipment squeezed into every available space. When these systems need upgrades or replacements, even a few centimeters of error can result in major clashes: a pipe spool that won’t fit, a valve handle that can’t be turned, or a vessel nozzle that collides with nearby supports. The cost of discovering these problems in the field is significant—leading to extended downtime, emergency rework, and safety risks for personnel.

This is where 3D scanning has transformed the game. By creating an accurate digital model of existing plant conditions, engineers can run clash detection before fabrication or installation ever begins. The result: right-first-time fit-up, reduced rework, and safer project execution.

The Challenge of Congested Piping

Traditional methods of surveying congested piping systems—tape measures, hand sketches, and selective 2D drawings—struggle to capture the reality of tight, multi-layered plant environments. Common challenges include:

Limited Access: Many areas are obstructed or hazardous, making manual measurements incomplete.

Cumulative Error: Small inaccuracies add up, leading to misaligned tie-in points.

No Spatial Context: 2D drawings cannot fully represent the three-dimensional complexity of plant environments.

These gaps often mean that prefabricated spools arrive onsite only to require extensive field adjustments—a costly and time-consuming form of rework.

How 3D Scanning Enables Clash Detection

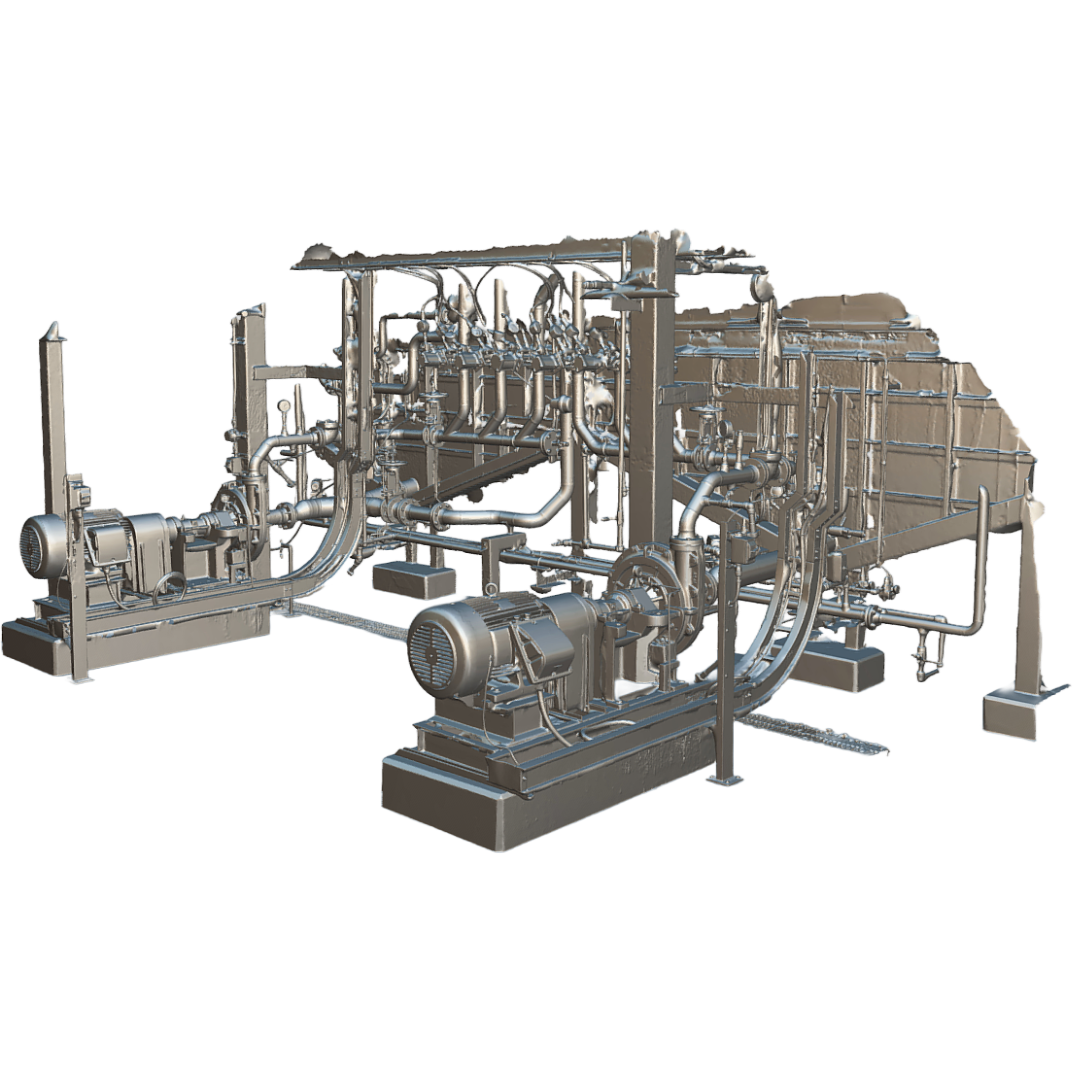

3D scanning technologies—ranging from long-range LiDAR to handheld metrology scanners—capture millions of data points across all surfaces in the plant environment. This creates a digital snapshot of the as-built reality with millimeter precision.

When this point cloud is imported into engineering design software, it becomes the foundation for:

Accurate As-Built Models: Every pipe run, flange, and structural member is represented digitally.

Simulation of New Designs: Proposed piping or vessels can be inserted into the model, aligned to actual tie-in points.

Automated Clash Detection: Software highlights where new designs intersect or interfere with existing infrastructure.

By resolving conflicts virtually, engineers ensure that fabricated components are constructible, accessible, and clash-free.

Benefits of Clash Detection with 3D Scanning

1. Reduced Rework and Downtime

Fabricated spools fit as intended on the first installation, eliminating costly site adjustments. Outage schedules become more predictable, reducing revenue loss from extended shutdowns.

2. Improved Safety

Less time is spent in hazardous environments for repeat measurements or emergency rework. Work crews operate with greater confidence knowing that interferences have already been eliminated digitally.

3. Optimized Prefabrication

With clash-free digital designs, contractors can maximize shop prefabrication, which is safer, faster, and more cost-effective than field welding.

4. Long-Term Value

The digital as-built model created during scanning remains useful for future upgrades, inspections, and asset management—beyond just the immediate project.

Conclusion

In industrial piping systems, where precision matters most, 3D scanning brings accuracy and foresight that traditional methods simply cannot match. By enabling clash detection in a digital environment, contractors and plant owners minimize risk, reduce downtime, and deliver projects with greater confidence.

As more industrial facilities embrace digital transformation, 3D scanning is becoming the new standard for safe, efficient, and cost-effective piping projects. The days of discovering clashes only after installation are over—today, the smartest teams find and fix them before fabrication even begins.