Precision in Practice: How Tolerance Management and Deviation Analysis Prevent Fit-Up Issues in Remanufacture

In industrial remanufacture, the smallest dimensional errors can create the biggest problems. When reassembling complex systems — turbines, pumps, compressors, gearboxes — a few tenths of a millimeter in misalignment can lead to vibration, leakage, uneven wear, or catastrophic failure.

Traditional measurement and inspection methods often fail to detect these issues early, especially when dealing with worn or non-standard components. As a result, many OEMs and maintenance teams still rely on trial assembly and iterative adjustments — a process that adds hours or days to critical downtime windows.

Enter tolerance management and deviation analysis powered by 3D scanning. This data-driven approach allows engineers to measure, compare, and predict fit-up issues before parts ever reach fabrication — turning reactive problem-solving into proactive precision.

Understanding the Concept: From Measurement to Insight

Tolerance Management

Tolerance management ensures that every component within an assembly fits together within predefined dimensional limits. Traditionally, tolerances were checked via manual gauges or coordinate measuring machines (CMMs). While accurate, these methods are slow, limited to discrete points, and unsuitable for complex or freeform surfaces.

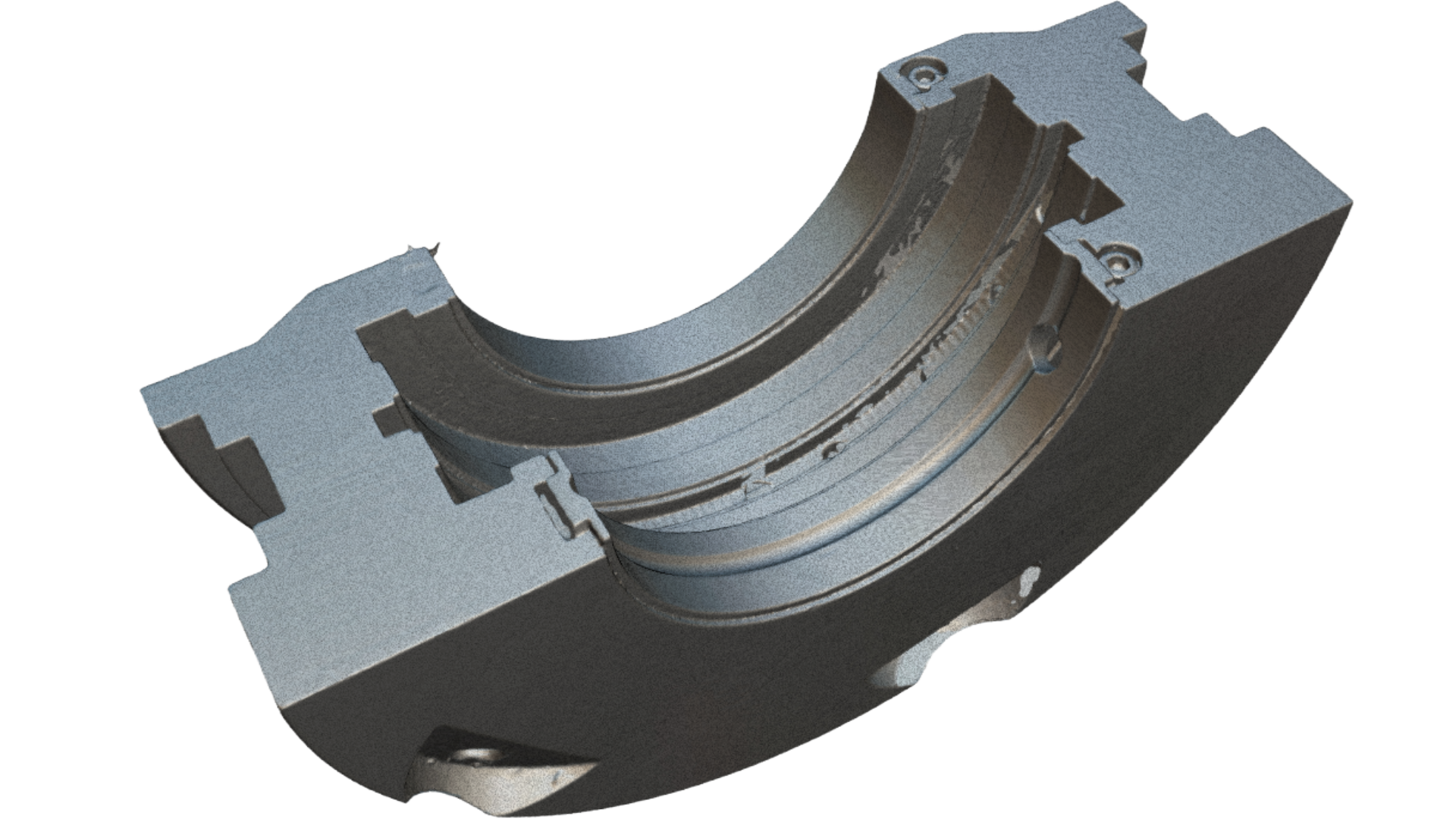

3D scanning changes the game. By capturing millions of surface points, scanners create a digital twin of the actual component. Engineers can then overlay this scan data onto the nominal CAD model to visualize and quantify deviation at every surface — not just at a handful of test points.

Deviation Analysis

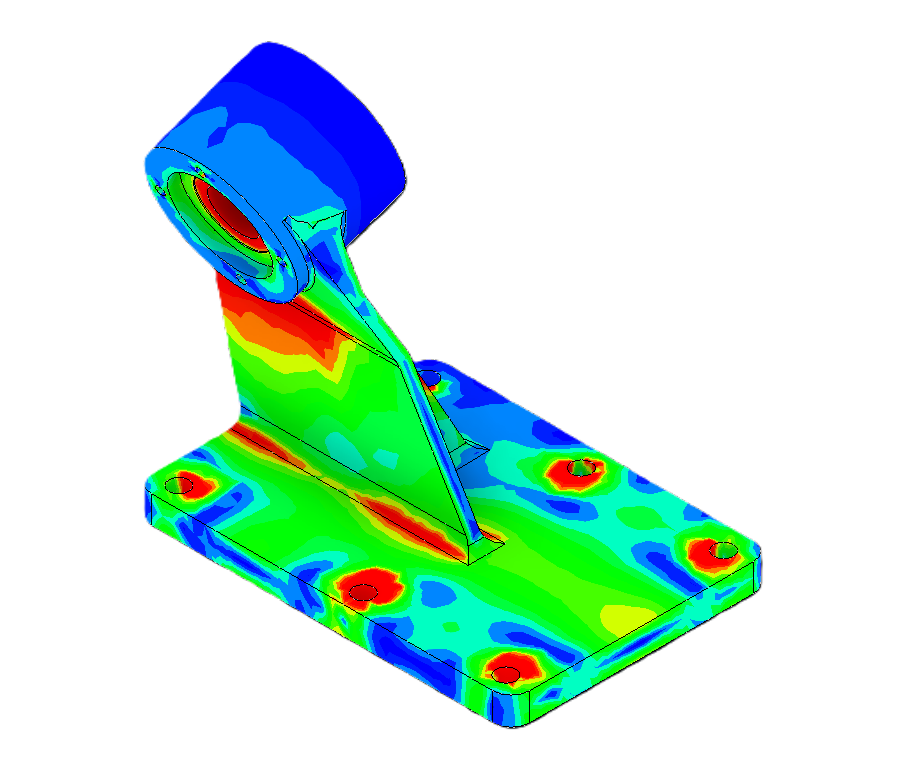

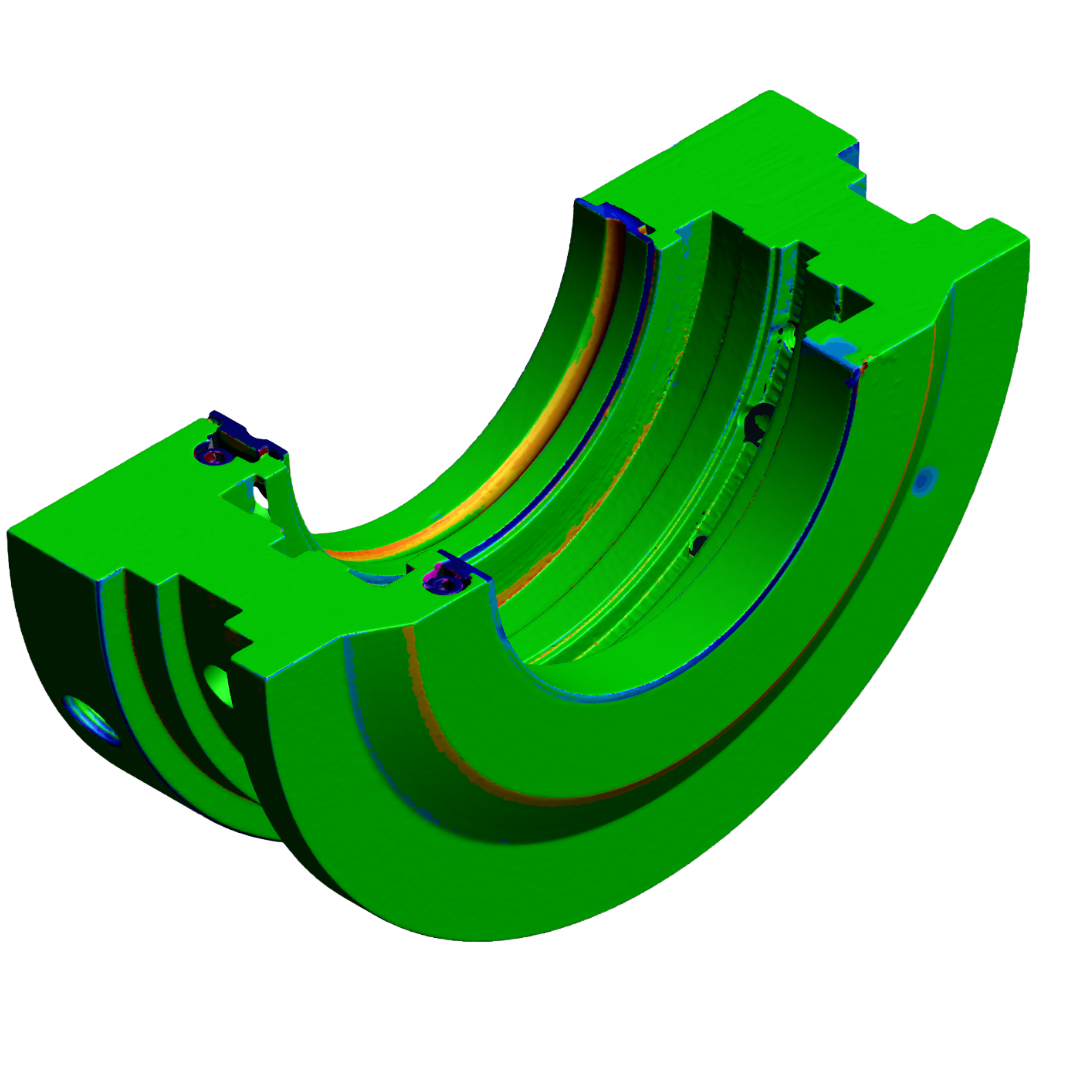

Deviation analysis uses color-mapped comparisons to show where real-world geometry diverges from design intent.

Green areas represent surfaces within tolerance.

Red zones indicate excess material or interference.

Blue zones reveal under-machined or worn surfaces.

This analysis gives a clear, visual diagnostic of dimensional variation — effectively predicting where fit-up issues are likely to occur.

The Process: Scan, Analyze, Correct

3D Data Capture

Using portable or fixed laser/structured-light scanners, technicians capture as-built geometry of parts or assemblies with accuracy up to ±0.02 mm.

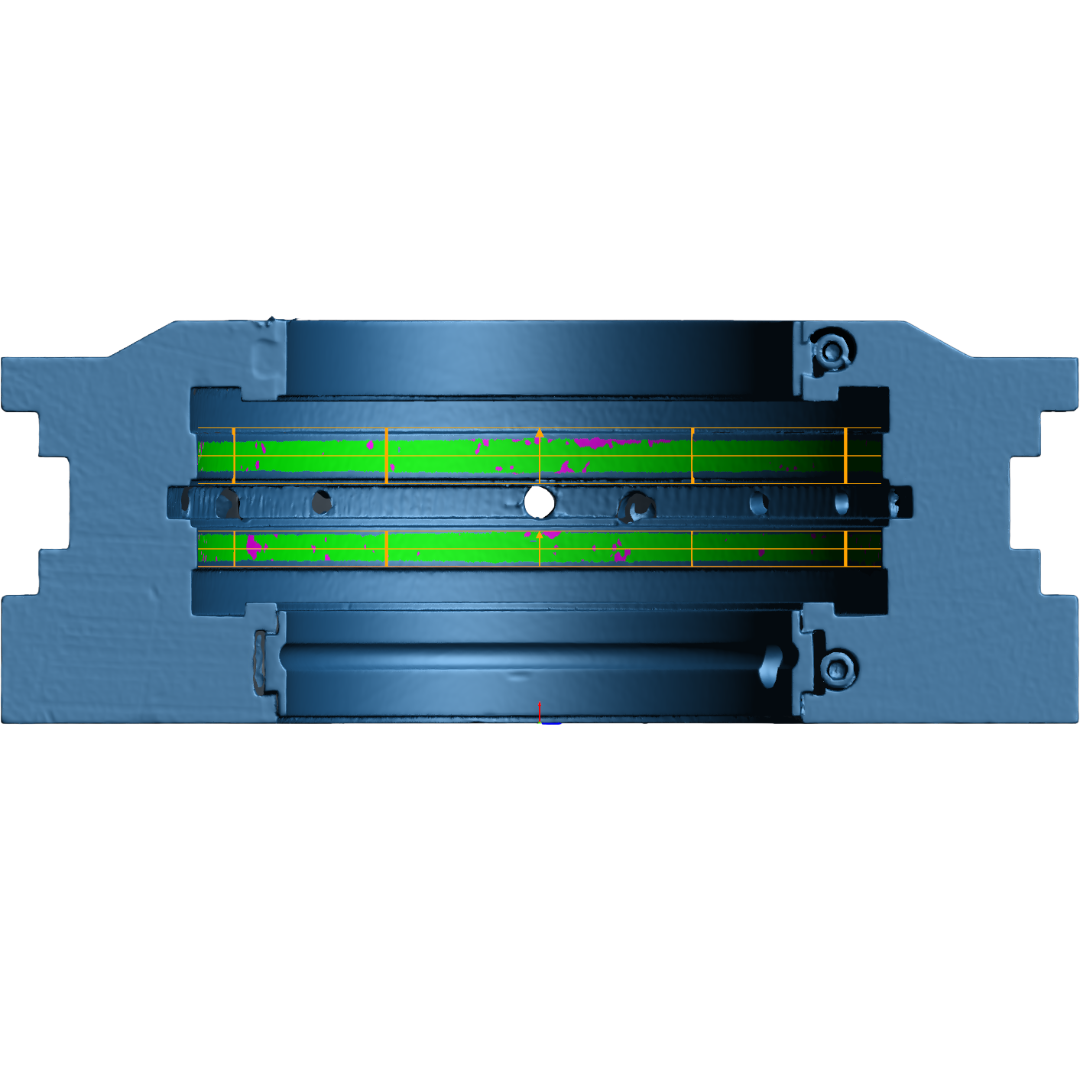

Alignment to Nominal CAD Model

The scan is aligned to the original design or reference geometry within reverse-engineering software such as Geomagic Control X, PolyWorks Inspector, or Artec Studio.

Tolerance Zone Definition

Engineers define tolerance thresholds (e.g., ±0.1 mm) for critical surfaces such as flanges, bores, or mating faces.

Deviation Mapping

The software generates a color-coded deviation map across the entire part surface, highlighting areas out of spec.

Fit-Up Simulation and Correction

Before manufacturing, engineers can simulate part assembly digitally, adjust machining allowances, or correct CAD geometry for perfect fit.

Post-Manufacture Verification

Once rebuilt or machined, the part is rescanned and verified to ensure all deviations are within tolerance limits — confirming fit before physical installation.

This closed-loop workflow eliminates uncertainty and provides complete traceability from measurement to manufacture.

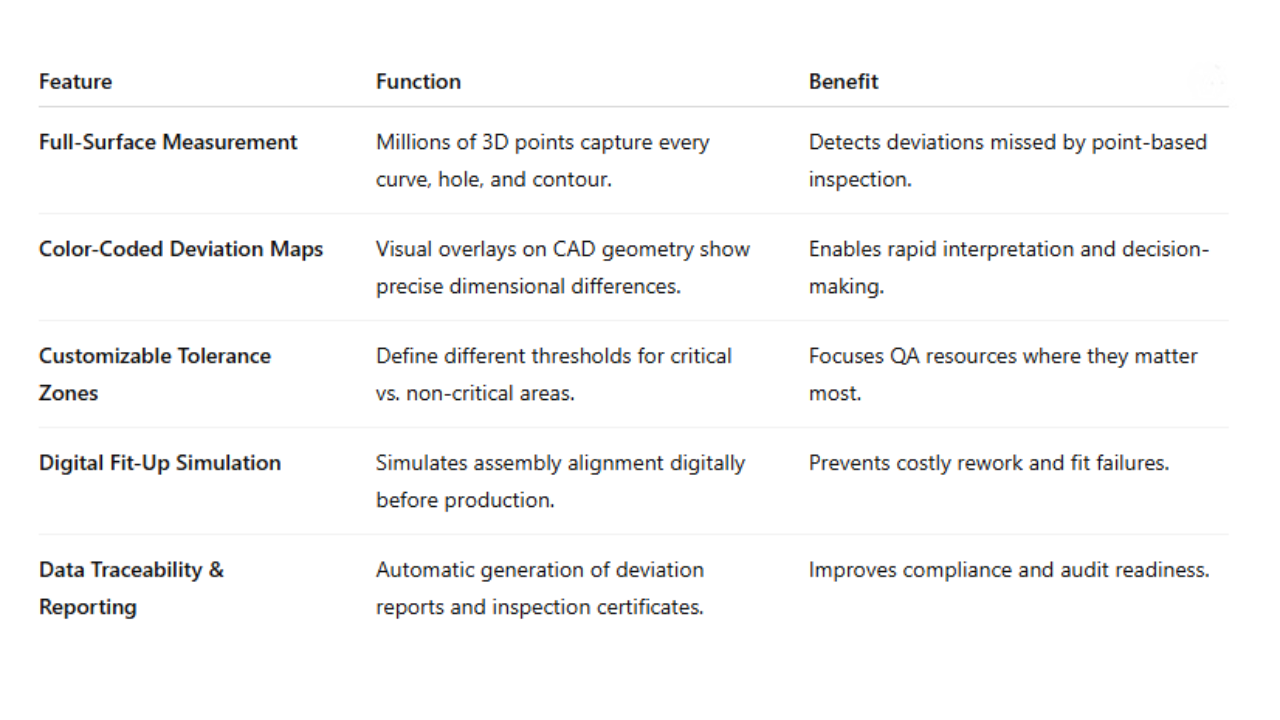

Key Features of 3D-Based Tolerance Management

Advantages for OEM’s

Reduced Rework and Scrap

By detecting deviations early, OEMs prevent misfits and machining errors that lead to wasted materials and time.

→ Typical rework reduction: 60–80%.Faster Quality Assurance

Automated deviation mapping accelerates inspection cycles and shortens sign-off times.

→ Inspection time savings: 50–70%.Enhanced Design Feedback Loop

Real-world geometry informs future design improvements, helping OEMs close the gap between as-designed and as-built.Digital Documentation for Compliance

3D deviation reports serve as verifiable quality records, critical in aerospace, energy, and defense sectors.

Benefits for Industrial Facility Owners

Predictable Maintenance Outcomes

Facility owners gain confidence that every replacement or remanufactured part will fit perfectly on the first try.Minimized Downtime

By eliminating unplanned rework and on-site machining, facilities get equipment back online faster.

→ Downtime reduction: 30–50% in overhaul operations.Extended Equipment Life

Continuous deviation tracking helps identify gradual wear patterns, enabling predictive maintenance before failures occur.Improved Collaboration with OEMs

Digital deviation data allows operators and OEMs to communicate with the same visual reference, reducing interpretation errors.

The Bottom Line: Precision You Can Measure

Tolerance management and deviation analysis transform maintenance and remanufacture from an art into a data science. Instead of discovering fit-up issues on the shop floor, engineers can now predict, visualize, and correct them digitally.

For OEMs, that means fewer quality escapes and faster delivery. For facility owners, it means greater reliability, less downtime, and measurable ROI.

3D scanning doesn’t just measure parts — it produces confidence.